Fluid conditioning is one of the most important aspects of maintaining your hydraulic system. If you don’t keep your hydraulic fluid clean and contaminant-free, your hydraulic system is destined to fail.

What Causes Hydraulic Fluid Contamination?

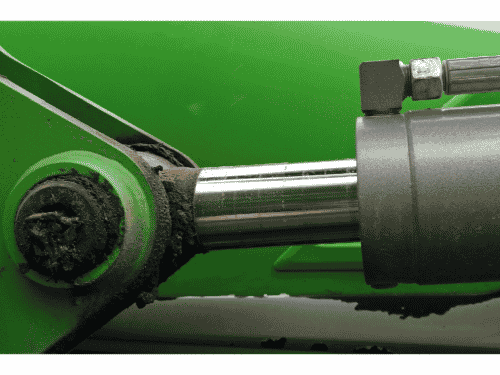

Hydraulic cylinder contamination occurs when air particles, metal, grime, or plastic are present in hydraulic fluid. These particles can create a blockage in the hydraulic system, causing your system to work less efficiently and potentially leading to hydraulic cylinder failure.

The good thing is, preventing hydraulic cylinder fluid contamination is easy once you understand the common causes.

Hydraulic Seal Failure

Worn or damaged hydraulic seals allow air, dirt, and other contaminants to pass through your system and cause hydraulic cylinder failure. Using the correct type of seal, along with proper installation, helps prevent premature hydraulic seal failure. Also, remember to replace worn or damaged seals as part of your annual cylinder maintenance program.

Low-Quality Hoses and Fittings

Buying cheaper hoses and fittings might save money but can cost you more down the road. Low-quality hydraulic components cannot withstand chemicals and harsh environments as well as higher quality products. Accelerated corrosion and wear also cause problems by loosening critical connections and allowing contaminants to pass through the hydraulic seal.

Hydraulic Cylinder Contamination During Manufacturing

Even cylinder production can cause fluid contamination. You can’t control manufacturing processes, but you can buy your hydraulic cylinders from manufacturers that practice quality control and fluid cleanliness during manufacturing.

Introduction of Contaminants During Routine Maintenance

Preventative maintenance and inspection improve performance and extend your cylinder’s lifecycle. However, replacing fluid or disassembling and reassembling hydraulic components can introduce airborne particles and other contaminants to fluid. Keeping a clean work area can help prevent these issues.

- Clean surfaces before you begin working

- Don’t open repacking kits or replacement parts until you are ready to use them

- Wipe exterior components with a clean, lint-free shop rag before reassembling your hydraulic cylinder

Poor Filtration

Contamination comes from internal and external sources. Good filtration protects your parts from fluid contamination and keeps things working smoothly. But using the wrong filtration product or cutting corners during installation can cause hydraulic cylinder contamination. Invest in high-quality filters and replace them on a regular schedule to keep hydraulic fluid contaminant-free.

Prevent Fluid and Hydraulic Cylinder Contamination

Clean fluid keeps your hydraulic system performing efficiently and prevents premature component wear. Understanding the common causes of hydraulic fluid contamination and taking preventative measures will minimize your risk of hydraulic cylinder contamination and system failure.

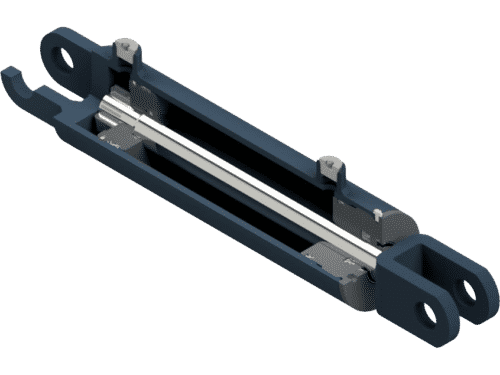

Aggressive Hydraulics understands the importance of hydraulic fluid conditioning and preventing fluid contamination. Our custom hydraulic cylinders are designed to perform at the highest level in every area, including hydraulic fluid conditioning.

We also offer hydraulic cylinder repair, so if you’re dealing with fluid contamination or other functional issues, we can help. With Finite Element Analysis technology, your cylinder will be as good or better than before.

Want more information about our Purpose-Built™ cylinders or our repair program? You can reach us at 866.406.4100 or send us a message.