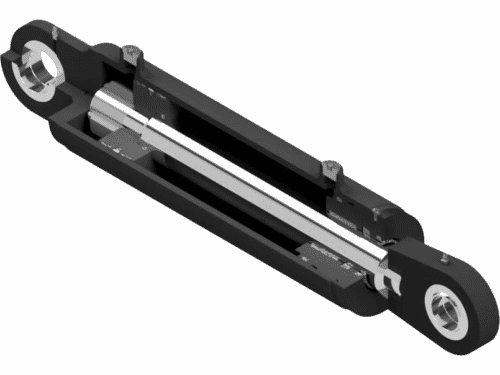

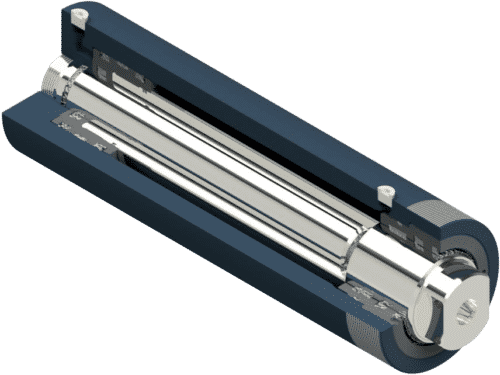

Given the demanding role hydraulic cylinders perform in a variety of applications, a strict maintenance schedule and inspection plan must be followed.

The number one thing you can do to achieve long life and optimum performance is to ensure that the right hydraulic cylinder is being used for the job. Anytime a piece of equipment or machinery is taken down for general maintenance or repair, it should be evaluated for job effectiveness.

Follow the tips below help cylinder identify potential issues and prevent unscheduled downtime:

-

- Ensure adequate filtration system for hydraulic fluid. Check for dirt or foreign materials in the fluid with regularly scheduled samples sent out for analysis. Inspect the filter for any clogs.

- Inspect the cylinder rod for signs of weakness or stress. A rough, bent, or scored rod will damage seals or allow for leaks. Inspect sealed area of the system components and fluid lines for evidence of leaks. Examine all lubricated areas and replenish as needed.

- Review Cylinder Tube for signs of ballooning and/or machine interference which can cause serious leaks, damage and even cylinder failure.

- Check for side loading, which if not corrected, can lead to misalignment, tube scoring, and bearing wear and damage beyond repair.

Whether you need a Purpose-Built™ cylinder or a replacement cylinder, Aggressive Hydraulics is the best source for all your hydraulic cylinder needs. To learn more, send us an email or call us at 866.406.4100.