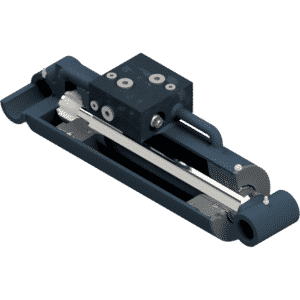

Base Mount

Base mounts are located on the opposite end from the hydraulic cylinder head. Responsible for securing your hydraulic cylinder to the body of your equipment, base mounts are a versatile alternative to welding a base, making repairs and maintenance a more straightforward process.

- Either welded to end cap or integral with end cap

- Precise machining of pin bore and mount width to ensure fit to machine mount points

- Bushing or bearings available to increase durability

Common Base Mounts

Threaded Base End (Female)

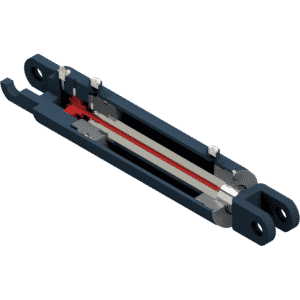

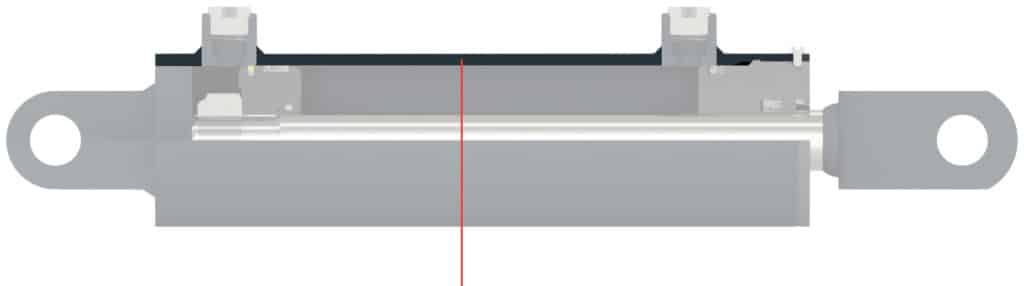

Internally Threaded Head Gland

Internally threaded head glands undergo rigorous quality testing to ensure USA-built performances and extreme reliability. These hydraulic cylinder components are responsible for holding seals, wiper, and bearings to allow your equipment to operate as designed.

- High-strength ductile iron

- Cylinder is fully serviceable by unthreading the head gland with a spanner wrench

- Radial screw resists head from unthreading during operation

Piston

Pistons are located within the barrel of a hydraulic cylinder to bear the hydraulic fluid’s force, allowing the cylinder to extend or retract. Pistons are used in single-acting and double-acting cylinders and are often machined with several grooves to keep seals in place.

- High-strength ductile iron

- Standard bi-directional piston seal and wear bearings

- Retained with nylon inserted lock nut

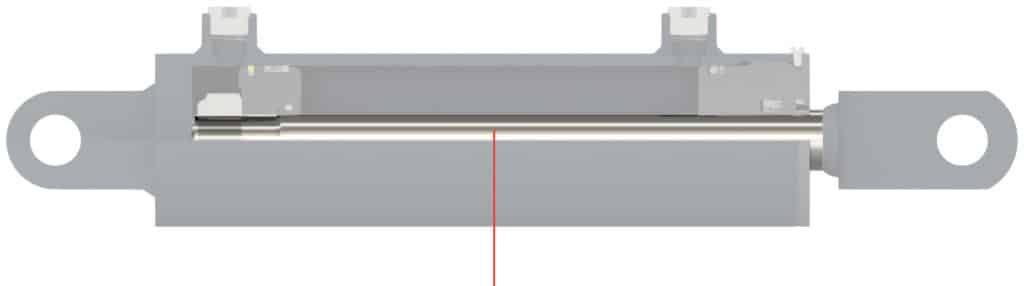

Rod

Hydraulic cylinder piston rods are attached to the piston and extend through the cylinder head. Rods are responsible for connecting the cylinder to your equipment, and any required mounting attachments will connect to this component.

- Chrome-plated high-strength steel

- Designed to withstand maximum tensile and buckling loads for the application

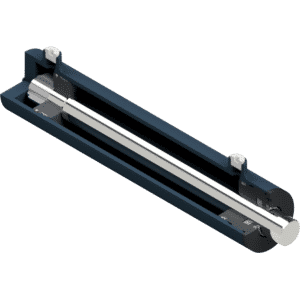

Rod Mount

Rod mounts are used to connect hydraulic cylinders to equipment and machinery. Rod mount cylinder components establish and maintain alignment, protect your cylinder from side load, and are connected to hydraulic cylinder rods. Many sizes and configurations are available to match your specifications.

- Typically welded robustness

- Threaded options are available for serviceability or length adjustments

- Bushing or bearings available to increase durability

Common Rod Mounts

Threaded Rod End (Female)

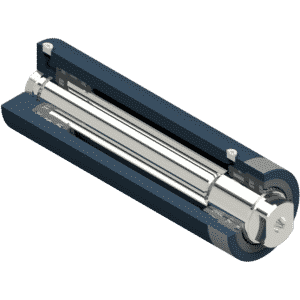

Tube/Barrel

Hydraulic cylinder barrels contain the piston and piston rods. This hydraulic cylinder component is enclosed at one end by a cap and the other by a gland. Also known as the tube, the barrel stands up to the harsh conditions and rugged demands of any application.

- Tough carbon steel

- Standard 3:1 design safety factor for burst based on material strength and maximum application pressure

Welded End Cap

Welded end caps from Aggressive Hydraulics provide consistent and reliable weld joints. Manufactured by certified welders utilizing highly precise procedures, our welded end caps are USA-made to provide long-lasting and durable performances in any hydraulic cylinder.

- J-groove weld preparation

- High-strength weld wire

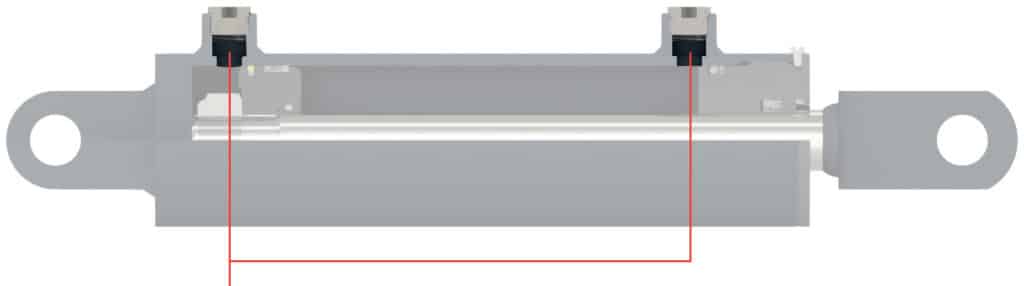

Welded Ports for Extend & Retract

We offer a wide variety of welded ports to meet the needs of any custom-made hydraulic cylinder. These critical components allow fluid to flow in and out of the cylinder and produce motion. Ports should always be an essential consideration in any custom hydraulic cylinder design.

- Size and type can be freely specified regardless of bore size

- Ports can be located at any position around the tube circumference