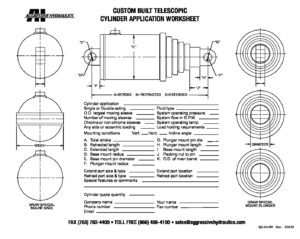

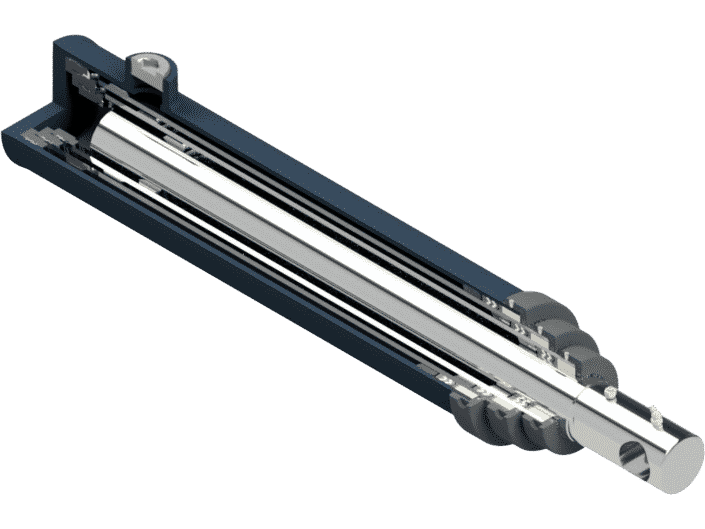

Application-Specific Telescopic Cylinder Designs

Telescopic hydraulic cylinders utilize multiple nested stages, achieving a long working stroke in compact/retracted form. Aggressive Hydraulics designs and engineers application-specific telescopic cylinders, Purpose-Built™ to withstand demanding applications and work environments.

An experienced engineering team helps you work through design considerations to ensure your cylinder meets your requirements. Choose from the following custom telescopic cylinder design options:

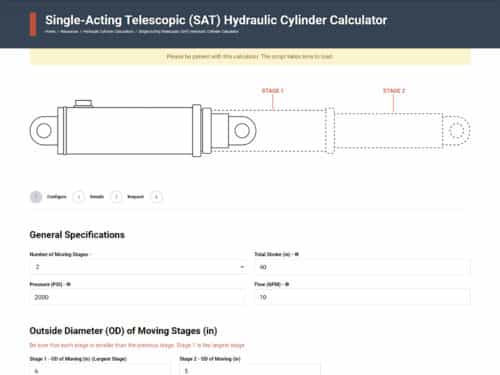

- Single-acting telescopic cylinders

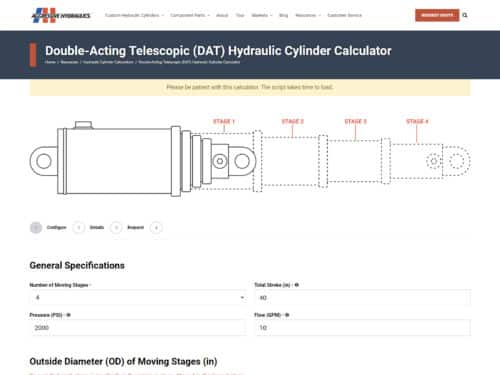

- Double-acting telescopic cylinders

- Combination of single- and double-acting telescopic cylinders

Customized to Your Equipment and Application

Purpose-Built™ designs ensure that you get the best performance from your custom telescopic cylinder. Experience across various markets and hydraulic applications helps us understand your unique challenges and design the best solution for the equipment and operating environment. Typical applications for our custom telescopic cylinders include: