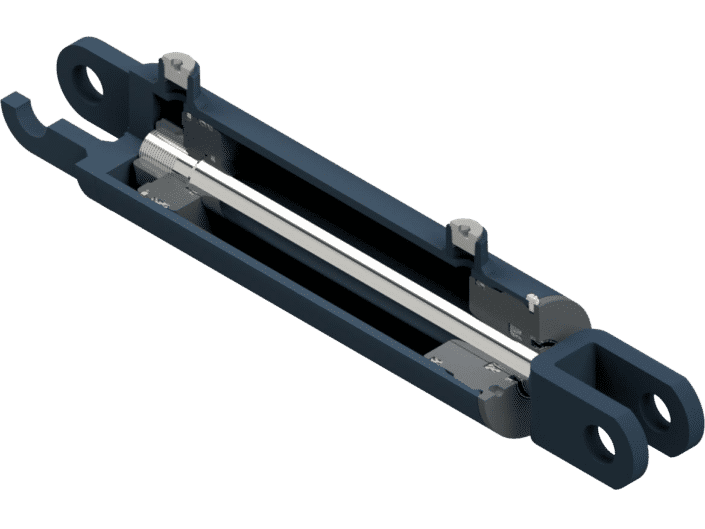

800 Series Cylinder Features

- Clevis style base and rod mounts

- 3000 PSI Heavy Duty Type

- Cold drawn (high impact) 75,000 min.yield D.O.M. tubing

- Ground & polished, hard chrome plated rods (75,000 min. yield)

- Welded style construction certified to A.W.S. B2.1

- Internally threaded head design with buttress threads

- Highest quality seal configurations compatible with petroleum base fluids

- Increased bearing length on both head & piston

- Ductile iron head gland & piston

- Piston utilizes wear bearings

- Nylon inserted lock nut

- Standard paint; black primer