A hydraulic displacement cylinder is an extension-only cylinder that uses load weight and gravity to retract. They are used throughout a variety of applications and move many types of equipment. Also called plunger cylinders, displacement cylinders are a low-maintenance and low-cost option for most markets, providing long-lasting and dependable performances even in challenging environments.

How Do Plunger Cylinders Work?

Displacement cylinders operate by oil displacing the cylinder rod. As the rod only pushes on the outward stroke, the cylinder must rely on the load or another force to return to a closed position. This process removes corrosion issues associated with other single-acting cylinder designs as no breather for air is necessary. Plunger cylinders feature a single port, simple construction, and only require one feed for effective operations.

What is the Difference Between Single-Acting Cylinders & Displacement Cylinders?

A displacement cylinder is very similar to a single-acting hydraulic cylinder. Both are extension-only designs that use load weight, gravity, or other forces to retract. However, a few key differences exist. Most notably, a displacement cylinder does not include a piston seal, resulting in less force generated during normal operations than a single-acting cylinder of the same size. This feature also allows displacement cylinders to extend more quickly, meaning that a smaller pump can produce appropriate rod velocity.

The best choice for your equipment will depend on the machinery’s specifications, anticipated load requirements, and other factors.

When Should I Use a Displacement Hydraulic Cylinder?

Displacement cylinders are best used as lift cylinders in simple operations, such as in forklift masts, aerial devices, agricultural equipment, and any other machinery that needs to be raised or lowered. Displacement lift cylinders can help your OEM or other manufacturing outfit produce machinery with dependable operations for a lower assembly price. Despite their many advantages, plunger cylinders do have a few limitations that are important to keep in mind.

Displacement Cylinder Advantages

- Low upfront & operational costs

- Low maintenance requirements

- Reduced risk of corrosion due to the oil-filled bore

- Simple construction

Displacement Cylinder Disadvantages

- Needs an outside force to retract

- Generated force relates to rod diameter and not tube diameter

- Limited range of applicable hydraulic valves

- Less control than double-acting hydraulic cylinders

Aggressive Hydraulic Purpose-Builds Displacement Cylinders to Your Specifications

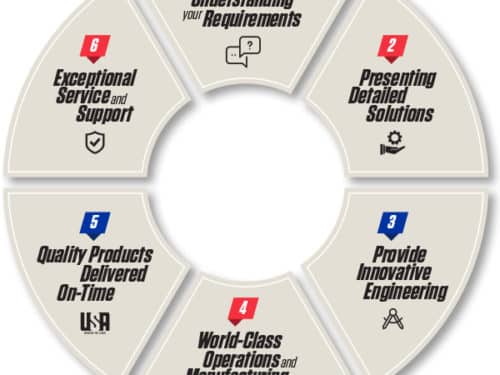

At Aggressive Hydraulics, quality isn’t just a department—it’s a company-wide commitment. Our team is dedicated to designing, engineering, and manufacturing Purpose-Built™ hydraulic cylinders that match your specifications and exceed your expectations. We build every cylinder to order, ensuring you receive personalized service and tailor-made solutions at every step of the process. If a displacement cylinder is not your best option, our engineers will work with your team to find the right cylinder configuration for your planned job.

Contact us or download our catalog to learn more about our processes, capabilities, and vast industry knowledge. Request a quote to receive information specific to your order.