Given the fact that fluid power equipment is one of modern mans oldest technological advancements, it’s only been in the last two hundred years that it’s actually been put to use in very productive ways. Advancements in alloys, and machining, along with a better understanding of mechanics and engineering have lead to precise advancements.

The first real practical application of hydraulic cylinders was during the 1800’s in the hydraulic press. Presses were used for all sorts of applications. Most often, dies were placed under the press and metal was formed, or cut over them to create a precise shape. Up until this time, metal needed to be cut and formed by hand, taking far more effort, and time, than the power and ease hydraulic cylinders could provide. Metal fabrication could move at a pace unheard of after hydraulic cylinders were utilized.

By the mid 1800’s the use of hydraulic cylinders for lifting on cranes was developed. A hydraulic cylinder was connected to a series of sheaves to multiply the movement of rope or chain for lifting. What was previously accomplished by hand, could now be done much safer and efficiently. Early cranes could lift up to five tons and hold it safely overhead, which made loading goods on ships and trains for commerce much faster.

Water was still being used at this time to provide the force inside the hydraulic cylinders. The city water supplies were often unreliable sources because of fluctuating pressure of about 90 psi. It was discovered that the use of accumulator tanks could provide much greater, and more consistent pressure as high as 700 psi. This discovery rapidly expanded the use of the hydraulic cylinder, and allowed for greater mobility for it’s installation.

As use spread, installations on buildings for lifting goods in factories and elevators became common. The advancement of using accumulator tanks, pulleys, and sheaves allowed hydraulic cylinders to be mounted on the sides of buildings. Combined with ropes and chains, the forces could be brought inside a building easily to be utilized without the bulk and noise of the heavy equipment. With the crane, and the elevator, there was no limit to how high buildings could be constructed.

Other industries and professions started to utilize this newfound technology. Textiles began using balers for cotton and wool presses. The military began using hydraulic cylinders to control large cannons on ships and on land. Farmers began automating machinery in the production of food. By the mid 1900’s hydraulic cylinders had come down in size and weight, and could be put on mobile platforms, opening up the use of hydraulic cylinders to most every industry imaginable.

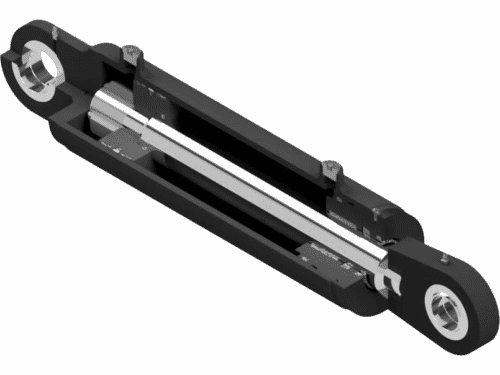

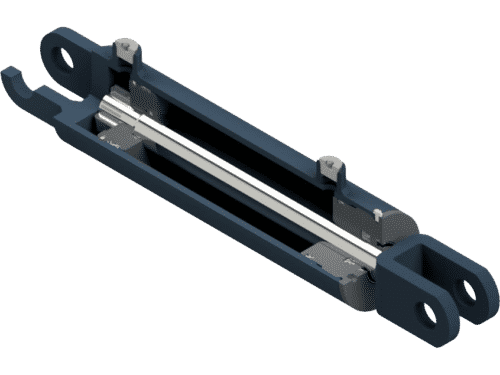

The advancement of technology continues today. With each application presented to us at Aggressive Hydraulics, comes new ideas and innovations. Mounting solutions, alloys, and materials research is part of every project. If you have a question about your own Purpose-Built™ application, give us a call at 866-406-4100 our engineers are always excited to develop the right solution for your project.