Hydraulic cylinder misalignment is a leading cause of complete cylinder failure. It occurs when a load deviates from the centerline of the cylinder rod, putting stress on seals, pistons, and other component parts. As these parts are not typically built to withstand this added force, they fall out of alignment quickly, resulting in costly shutdowns or irreparably damaged equipment.

Signs of Hydraulic Cylinder Misalignment

The misalignment of two cylinders can happen when the cylinder is extended or retracted. Sometimes misalignment can go undetected until your equipment breaks down, so it is important to conduct regular maintenance checks. Signs of misalignment include:

- Bent cylinder rods

- Scuff marks on one side of an extended rod

- Uneven wear in the rod-eye or cap-end clevis

- Cocking or bowing during extension strokes

- Buckling mounts or damaged mounting blocks

- Abnormal wear on pins

4 Design & Engineering Considerations to Avoid Hydraulic Cylinder Misalignment

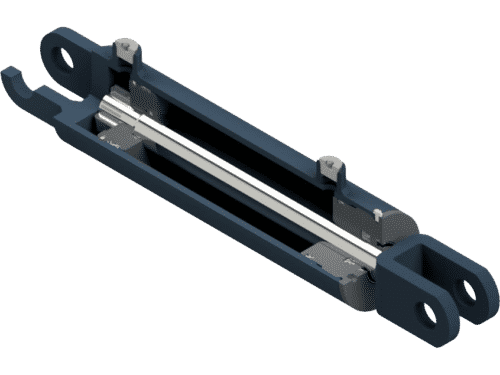

Choose the Right Cylinder Mounts

Hydraulic cylinder mounts hold your cylinder in position and help prevent wear caused by shock. Choosing the right mount based on your cylinder design, equipment goals, and planned specifications will improve performance while minimizing cylinder misalignment. There is no one-size-fits-all answer, and your best option may include vertical bit mounts, self-aligning mounts, spherical bearing mounts, or others.

For example, heavy-duty cylinder designs with long strokes have higher mount strength requirements, making a flange or foot mount your best option. Other factors impacting the best mount to avoid cylinder misalignment include space constraints and non-standard specifications.

Consult an experienced hydraulic cylinder manufacturer to learn more about your options.

Calculate Your Required Load Carrying Capacity to Determine the Best Rod Size

Load affects every part of a hydraulic cylinder. Your bearings, couplings, and other components must have the correct load capacity to maintain proper cylinder alignment. Components made from high-strength materials will offer better durability than lightweight options. This is especially true of rods, which are the most important aspect of any hydraulic cylinder.

Load capacity is calculated by multiplying your cylinder’s PSI by the effective area. You can select the best rod size for your cylinder using this value. A basic rule of thumb for determining cylinder rod sizing is the higher the load requirements, the larger the rod diameter. If a rod is too small, it may become bent or broken. If it is too big, the cylinder will misalign during normal operations.

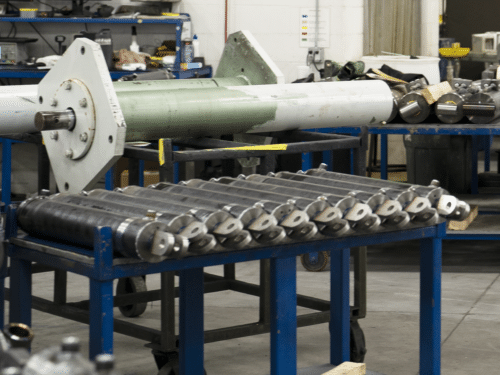

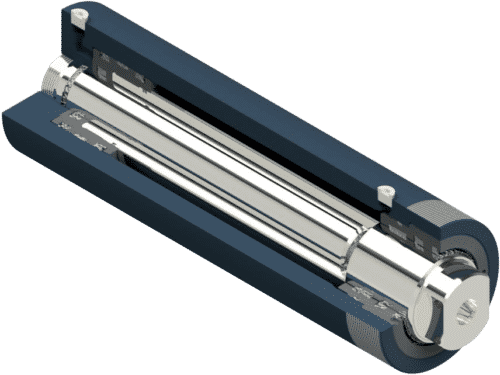

Incorporate Cylinder Stop Tubes

Certain cylinders feature a long stroke and are more prone to side loading, misalignment, and other issues. One solution is a cylinder stop tube. These metal collars sit between the piston and head to provide additional bearing support as the cylinder pushes a load and act as an alternative to oversized cylinder rods.

Work with an Expert Hydraulic Cylinder Engineering & Manufacturing Partner

If the misalignment of two cylinders occurs immediately after installation, during initial use, or in the testing phase of your equipment manufacturing operation, an engineering mistake is the most likely culprit. Shoddy manufacturing, cutting corners, or engineers insufficiently understanding your requirements can all lead to cylinder misalignment, expensive shutdowns, and complete equipment failure.

Aggressive Hydraulics is here to help. We are a USA-owned and operated manufacturer of hydraulic cylinders Purpose-Built™ to your specifications. Our design and engineering team works closely with you to understand your requirements, goals, and planned jobs, ensuring you receive custom cylinders that are built to last. From implementing innovative design features to prevent misalignment to engineering component parts and configurations to match your needs through final delivery, we are your full-service partner for any hydraulic cylinder need.

Contact us today to learn more about how to avoid misalignment through Purpose-Built™ cylinder solutions. Request a quote to receive pricing and timeline estimates specific to your order.