Hydraulic dieseling, often called the dieseling effect, occurs when air mixes with hydraulic cylinder oil. The air forms bubbles in the hydraulic oil. When pressure is introduced to the system, combustion occurs, instantly burning and cracking the rod or piston seals and causing hydraulic cylinder failure. The explosive effect is similar to what happens when diesel fuel ignites in an engine, which is why it’s referred to as dieseling.

Causes of Hydraulic Cylinder Dieseling

- Negative Pressure in the Hydraulic Cylinder: If volume fluid demand exceeds the volume of fluid provided by the pump, negative pressure develops. That pressure results in air being drawn into the cylinder past the rod seals.

- Faulty Float Valves: Float valves perform well at keeping air out but still allow some air in. Faulty or incorrectly adjusted load control valves allow air to mix with the hydraulic oil, which can cause hydraulic dieseling. This issue is prevalent in excavators and other equipment with boom attachments.

- Improperly Purged Hydraulic Fluid Chambers: Dieseling can occur if the cylinder chambers are not correctly purged of air during commissioning.

- Loose or Worn Connections: Worn rod seals and loose hoses, suction lines, and connections can all allow air to enter the hydraulic system, increasing the risk of combustion.

Ways to Avoid Dieseling in Hydraulic Cylinders

Since hydraulic oil contamination is the main culprit in dieseling, your first step is to address any issues that could potentially introduce air to the hydraulic system.

- Inspect and maintain your hydraulic cylinders on a regular schedule. This should include checking all seals, connections, and working parts of the cylinder. Ensuring proper functionality of the cylinder is paramount to optimal performance and can help address needed repairs before cylinder failure occurs. Tighten loose connections and replace rod seals and components at the first sign of wear.

- Upon commissioning, fill the cylinder with clean hydraulic fluid through the service ports before connecting the hoses. This will help reduce the risk of dieseling caused by hydraulic oil contamination. Bleeding your hydraulic system before startup will also remove air trapped in the hydraulic oil.

- Cylinders should then be stroked without load several times, being especially mindful not to create pressure at the end-stroke. This process effectively purges air from the cylinder to prevent dieseling.

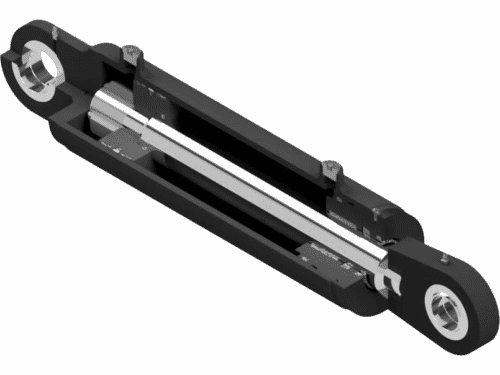

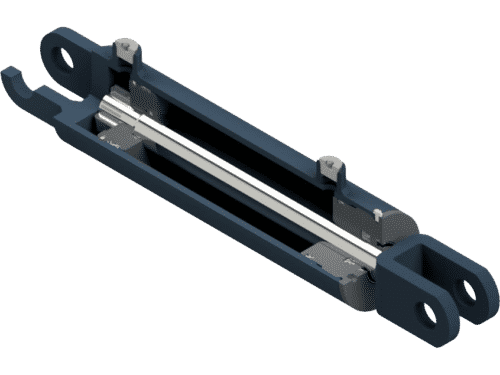

Aggressive Hydraulics has high-performance replacement cylinders and components for all of your business needs. Send us an email or call us at 866.406.4100 to learn more about our Purpose-Built™ , American-made cylinders.