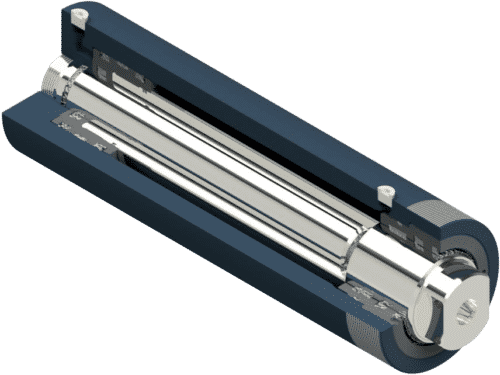

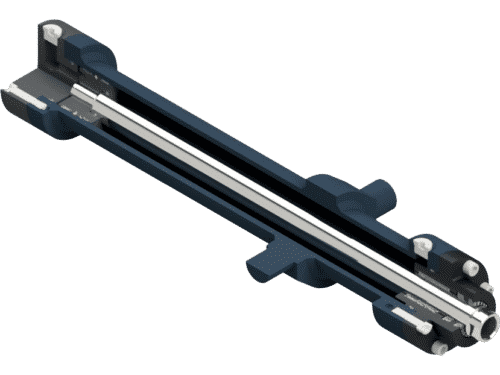

Mill-duty hydraulic cylinders are manufactured for any job in need of a durable, reliable product with low maintenance requirements. From quarries to steel mills and beyond, these heavy-duty hydraulic cylinders function at maximum efficiency in harsh environments, during extended operations, and in other tough conditions.

What Makes a Mill-Duty Cylinder Different?

Mill-duty cylinders operate in a similar way to other hydraulic cylinders. However, heavy-duty mill-type cylinders are explicitly designed for demanding applications in extreme job sites. They deliver enhanced reliability for mobile and industrial equipment and are built to match high pressure requirements, increased safety standards, and exceed other guidelines or regulations. These hydraulic cylinders are often made from special materials or plating, are easily serviced, and deliver excellent performances in most industrial settings.

Typical Features of Mill-Duty Cylinders

Mill-duty hydraulic cylinders have similar designs to welded rod cylinders but tend to have much thicker barrel walls and sturdier constructions to stand up to challenging jobs. While custom cylinder manufacturers can create the exact configuration you need, most mill-duty cylinders feature:

- Steel-flanged bolted end caps and heads

- Heavy-duty steel tubing

- Larger pistons and bearings

- Specialty mounts for heavy-duty operations

- Rated for higher pressure and safety standards

Mill-Duty Cylinders vs. NFPA Cylinders

Is a mill-duty or NFPA cylinder best? While these configurations share many traits and markets, they are each suited to different applications.

NFPA cylinders are built following guidelines set by the National Fluid Power Association to have standard designs, no matter the hydraulic cylinder manufacturer. They are suitable for basic operations, but due to their inherent standardization, they are not versatile options. Mill-duty cylinders offer enhanced functions and nearly unlimited custom manufacturing choices. They can be built to NFPA standards and often meet or exceed NFPA specifications while standing up to more demanding and specialized jobs.

Who Uses Mill-Duty Cylinders?

As denoted by the name, mill-duty hydraulic cylinders are often found in steel mills and foundries. The heavy-duty characteristics that make mill-duty cylinders ideal for steel mills also are applicable in a diverse range of markets:

- Mining, Quarry & Aggregates

- Oil, Gas, Wind & Solar Energy

- Industrial Equipment & Machinery

- And many other sectors!

If a mill-duty hydraulic cylinder is not the best fit for your steel mill or other operation, other robust options are available, including alternative heavy-duty hydraulic cylinders or high-pressure cylinders.

Purpose-Built™ Heavy-Duty Cylinders Manufactured in the USA

Aggressive Hydraulics is the top custom mill-duty hydraulic cylinder manufacturer for rugged applications and demanding industries. Each of our cylinders is Purpose-Built™ in the USA to ensure American-made quality on every order. From replacing cylinders in existing equipment to building completely new machinery designed to your specifications, Aggressive Hydraulics has the engineering and manufacturing experience to help you take your job site to the next level.

Contact Aggressive Hydraulics to learn more about how we can support you through the industry’s best Purpose-Built™ mill-duty cylinders. Request a quote to begin designing your custom hydraulic equipment. One of our expert engineers will be in touch as soon as possible.