Railways are not just an essential part of American commerce, but American history. In 1827, the first railway was laid for steam engines in Baltimore, Maryland. The first track was only 13 miles long and took three years to complete. By 1852, the Baltimore & Ohio (B&O) railroad was expanded to the Ohio River in Wheeling, West Virginia. For the next 100 years, these railways were laid entirely by hand, but when hydraulic cylinders were applied to rail equipment, rail expansion, and repair, was able to occur at a more rapid pace.

Of course, there are the obvious uses of hydraulic cylinders in the rail industry. Loaders and cranes to move equipment, and train cars, on and off tracks, as well as on loading and offloading goods for transport. There are several pieces of equipment however, that are used to build and repair track today, that use hydraulic cylinders to do the bulk of the work; tie cranes, spike drivers, ballast regulators, tie inserter/removers, and ballast tampers. Without this equipment, rail repair would be a labor-intensive process. Hydraulic cylinders have made it not only easier, but safer to do this work on America’s railways.

The History and Evolution of Hydraulics in America’s Railways

Tie Cranes

Tie cranes install new railroad ties or remove old ones. These hydraulic machines typically mount on lightweight rail trolleys that roll directly on the tracks under repair. A powerful gripper—driven by hydraulic cylinders—sits at the end of the boom arm. A hydraulic “wrist” joint rotates and tilts the gripper so crews position each tie with pinpoint accuracy. Additional hydraulic cylinders extend the boom far beyond the existing rails into the path of future track. This design lets one machine place or retrieve ties across long, remote routes without extra manpower.

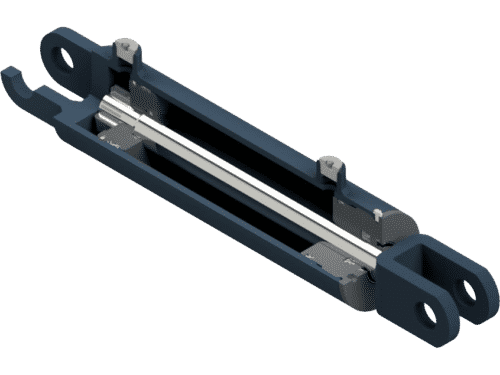

Tie Inserter/Remover

Tie inserter/removers operate as rail-mounted machines. They pull or insert rail ties without removing the overlying track. The machine deploys hydraulic cylinders to grip the exposed end of a tie. A second hydraulic cylinder extends an arm outward, perpendicular to the track, and extracts the tie for easy pickup by a tie crane. Operators insert new ties by reversing the exact process. This method swaps out damaged ties quickly. It eliminates lengthy track removals and keeps rail routes open with almost no downtime.

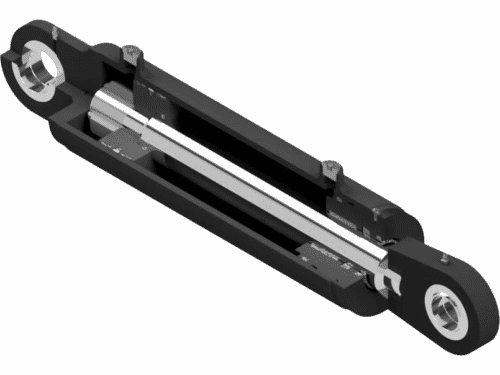

Spike Driver

Spike drivers have replaced traditional sledge hammers to drive the spikes that hold rail ties in place. Using a spike driver saves time, and eliminates over driving the spikes. Resembling a hydraulic cylinder with a handle on one end, and a socket for the rail spike on the other, a spike driver exerts downward force pushing a spike through a rail tie and into the earth below, holding the rail tie in place.

Ballast Regulator

Ballast regulators distribute and shape gravel beneath rails and ties. Hydraulic cylinders on these track-mounted machines control a center blade plus two side blades. These blades push gravel evenly to create the ideal profile for smooth, level track. Operators run these machines over existing tracks to guarantee proper ballast support. Precise hydraulic cylinders adjust blade depth and independent side angles. This capability keeps tracks perfectly level and within tolerances—whether straight runs or curves.

Ballast Tamper

Ballast tampers lift entire track sections—including rails and ties—and pack ballast gravel underneath. These massive track-mounted machines rely on complex hydraulics and mechanics. As the machine moves along the track, it detects sunken ties from train weight or erosion-sagged rails. Powerful hydraulic cylinders grip those sunken ties. A second set lifts them precisely into position and holds them perfectly level. A third set immediately packs fresh ballast underneath the raised rails and ties to lock them securely. At the same time, the tamper fine-tunes alignment. This keeps rails perfectly parallel and the track as straight as possible. Without hydraulic cylinders this complicated process could take several days for a short section of track.

If you’re in the rail industry, or any industry that uses hydraulic cylinders, and you’d like more information on how Aggressive Hydraulics® can help with the pushing, pulling, and heavy lifting in your industry, contact one of our Hydraulic Cylinder Specialists® at (866)406-4100, or check out our railway maintenance page for more information.