Benefits of Position Sensing Hydraulic Cylinder Technology

High-tech automation is often associated with manufacturing, but today, many mobile hydraulic and industrial applications rely on computer-aided SMART cylinder technology to improve speed, accuracy, efficiency, and safety.

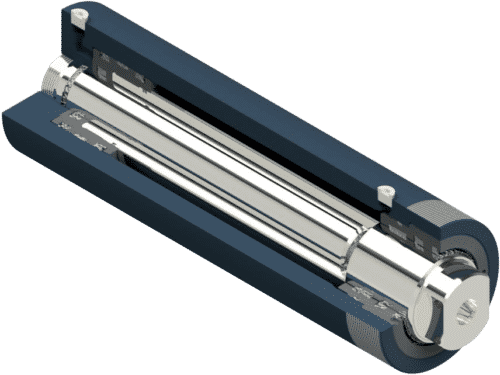

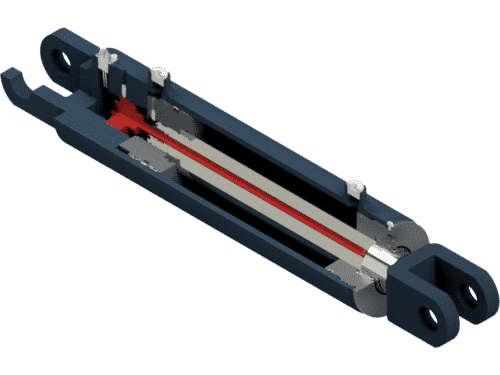

SMART cylinders aren’t necessarily new. In fact, they’ve been around for a while. These hydraulic cylinders feature internal or external sensors that send electronic position signals back to the main hydraulic system, allowing you to know exactly where a cylinder is in its stroke. With position sensing technology, you can control hydraulic cylinders individually or coordinate and synchronize the movement of multiple cylinders.

Reliable Load Holding and Improved Safety

There are several benefits to using position sensing hydraulic cylinders in your industrial or mobile equipment application.

Automation: Every industry feels the pressure to get things done faster and more efficiently. With SMART hydraulic cylinders, one person can simultaneously manage multiple pieces of equipment without sacrificing performance. Position sensing hydraulic cylinders also improve productivity by allowing equipment operators to increase cycle speeds safely.

Precision and control: Cranes and other load-moving equipment require precise, controlled load holding and movement, especially in applications involving heavy loads. The instantaneous feedback provided by SMART cylinders lets you know the exact cylinder position so that you can hold loads longer and control equipment movement more effectively.

High accuracy and repeatability: Applications like agricultural seeding/fertilizing, food processing, and demolition rely on predictable, consistent placement. By providing electronic feedback in real-time, position sensing hydraulic cylinders help equipment operators maintain straight lines and consistent heights, and accurately position equipment.

Safety: Any job site, from logging operations to underground mining, presents challenges and potential hazards. The load holding capabilities of SMART position sensing cylinders improves safety on the jobsite. Remote capabilities also enhance safety by allowing workers to control equipment from a safe distance. Plus, automating manual tasks helps prevent operator fatigue.

Watch and listen to Tony, an application engineer at Aggressive Hydraulics, speak to Fluid Power World about these and other advantages of using SMART hydraulic cylinder technology.

What to Consider in Specifying Your SMART Hydraulic Cylinder

Position sensing hydraulic cylinders come with different sensors, connections, and output types. Enclosed sensors are protected from physical damage and environmental elements. You can also find smart hydraulic cylinders with ingress protection ratings for applications where moisture penetration is a concern. Other standard specifications to discuss with your design engineer include stroke length, pressure requirements, bore size, material and plating, and special features required for your application.

Any application involving heavy equipment or where you need to move and control heavy loads can benefit from SMART hydraulic cylinder technology. Some of the markets that use positing sensing cylinders from Aggressive Hydraulics include:

Contact our application engineers to discuss using our custom position sensing hydraulic cylinders in your industrial or mobile equipment.