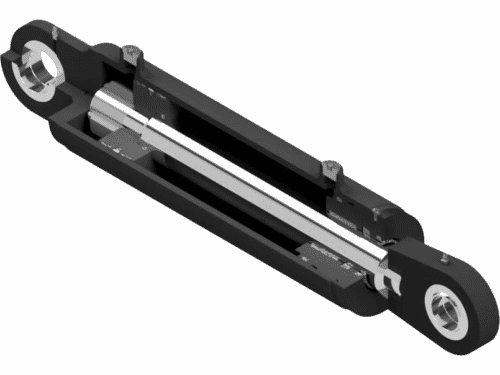

To ensure optimal performance, hydraulic cylinders should be maintained regularly throughout the year. Not only will you get the most out of your cylinder warranty period, but checking cylinders more frequently also reduces the need for replacement. When caught in time, cylinder repair is generally a more timely and cost-effective solution than a complete cylinder replacement.

Incorporate these tips annually to get the most from your hydraulic cylinders:

- Ensure proper Fluid Conditioning

Check for and remove any dirt or foreign materials in the hydraulic fluid. Be careful not to introduce aerated fluid which can cause sound level issues. Verify the filtration system is operating properly. Finally, inspect filter elements for clogs and replace as necessary. - Examine Rod quality & finish

It is extremely important to ensure the cylinder rod is in good condition. A bent rod can cause load shift. The wrong rod diameter or incorrect rod strength can cause a variety of failures. Be sure to inspect the rod finish as well. Worn seals are caused by too smooth of a finish, while leakage past the seal is caused by too rough of a finish. - Inspect Piston seals, holding valve, and rod seals

Check for leaks which can cause cylinder drift. Examine wipers, O-rings and seals which all help prevent contamination and leaks. Inspecting hydraulic fluid for contamination in step 1 also helps reduce cylinder drift. Ensure that all lubricants and replenish as needed. - Review Cylinder Tube

Ballooned tubes can occur when the wall of the cylinder is not thick enough or if the cylinder’s pressure is more than the material can handle. A ballooned tube can cause fluid to bypass the seal, which must be addressed immediately.

Do you want to learn more about reliable cylinders that can handle even the toughest jobs? Contact us today to find out about our Purpose-Built™ hydraulic cylinders. Give us a call at 866.406.4100.