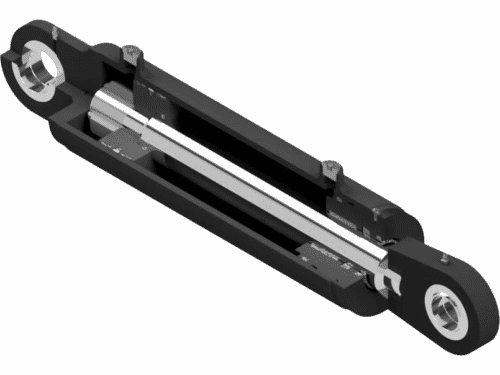

If a hydraulic cylinder fails, you have two choices: buy a new cylinder, or repair the old cylinder. Often times there is a reason for hydraulic cylinder failure. Aggressive engineers have several tools at their disposal to determine how and why a cylinder failed, and how to prevent it moving forward. Finite Element Analysis is one of those cutting edge tools.

Through the repair/replace process, we use advanced Finite Element Analysis (FEA) modeling to determine the strengths and weaknesses of a cylinder and to understand how it will react under stress in its application. FEA allows detailed visualization of where components bend or twist, and indicates the distribution of stresses and displacements before actually building the hydraulic cylinder or replacement components. The software used for FEA provides a wide range of simulation options for controlling the complexity of both the model and the application it’s used for. Similarly, the desired level of accuracy and cyclic time requirements can be managed simultaneously to address most fluid power applications. FEA allows entire hydraulic cylinder designs to be constructed, refined, and optimized before the design is ever manufactured on the shop floor, allowing Aggressive to create a Purpose-Built™ hydraulic cylinder that is engineered for your specific application.

What does this mean for the end user? Materials can be spec’d based on the application and forces needed. The result is a stronger, more durable cylinder for your fluid power application. In many cases, our precision manufacturing process results in a cylinder that outperforms the original part. Put Finite Element Analysis to use for you by contacting an Aggressive Hydraulics engineer at 866-406-4100.