While many industries use specialized equipment, there’s only one that uses it hundreds of feet underground in dangerous, unpredictable, and untouched environments. In the underground mining world, hydraulic equipment failure could be devastating to the people operating these massive machines. This is why using Purpose-Built™ hydraulic cylinders is so important for the mining industry.

The Role of Hydraulic Cylinders in Underground Mining Equipment

One of the more common machines used in coal mining is a continuous miner. This machine has a large rotating steel drum equipped with tungsten carbide teeth that scrape the coal from the seam. These operate in underground areas that have been cut into the coal bed, mining up to five tons of coal per minute.

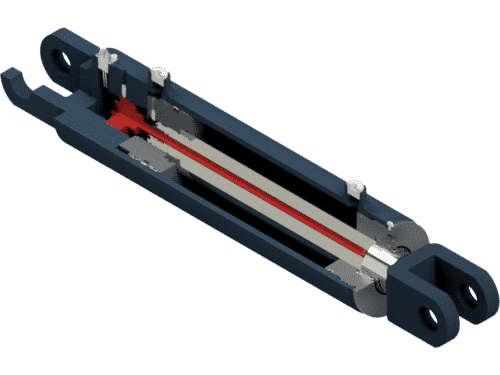

In continuous miners, hydraulic cylinders position the steel drum that does the cutting, move, and position the equipment so it can advance underground while supporting the ceiling.

Longwall mining is a highly productive coal mining technique using machines with multiple coal sheers mounted on self-advancing hydraulic ceiling supports. These underground mining machines are massive, about 800 feet in width and 5-10 feet tall. The shearers cut coal from the wall face, allowing it to fall to a conveyor belt for removal. Longwall miners can remove areas of coal as wide as the machine and up to 12,000 feet long.

Hydraulic cylinders are used to position longwall mining equipment, operate the shears, and support the ceiling. Strength and reliability are key to keeping the operation functioning efficiently and providing a reliable and safe work environment for equipment operators.

Safety and Preventing Catastrophic Events

Reducing the chance of collapse is a primary concern in any underground mining operation. So, what keeps massive tunnels from collapsing? Roof bolting prevents tunnels from collapsing on workers as the mining equipment advances through the tunnel. Here, coal mining hydraulic cylinders lift temporary roof supports into place while holes are drilled into the tunnel ceiling for permanent bolts and support plates.

Hydraulic cylinders also move the drill and bolter position under the tunnel roof to allow for more efficiency without moving the machinery in the tunnel. Larger roof bolters, called crawlers, are track mounted and increasingly remote controlled. Position sensing cylinders can be used in these situations to automate positioning, allowing workers to control equipment from a safe location.

Hydraulic Cylinders for Surface Mining, Hauling, and Material Handling

The use of hydraulic cylinders extends far beyond coal mining equipment. Surface mining equipment, dump trucks, crushers, and countless other types of machinery rely on hydraulic power to ensure precision, performance, and safety under extreme work conditions.

Dump trucks use telescopic cylinders to lift and dump heavy loads. Crushers rely on high-power hydraulics for aggregate production. Hydraulically powered conveyors and material handling equipment enable the safe transport of heavy materials. Hydraulic cylinders are and always will be an essential part of these and other mining and transport equipment designs.

The Purpose-Built™ Difference

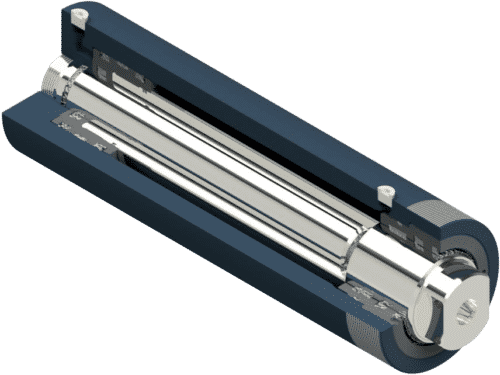

Mining equipment requires hydraulic cylinders to function and keep the personnel working in and around mining sites safe. Aggressive Hydraulics works with the surface and underground mining industries to develop Purpose-Built™ solutions for mining equipment. Our engineers design hydraulic cylinders that optimize equipment performance under extreme and demanding conditions while improving safety on the job.

Contact us at (866)406-4100 to speak with an engineer about using Aggressive Hydraulics Purpose-Built™ hydraulic cylinders in your application.