Tie-rod cylinders and welded cylinders rank as the two most common hydraulic cylinder types. Both designs power hydraulic systems. Yet they differ in several key ways. Each excels in specific applications and operating conditions.

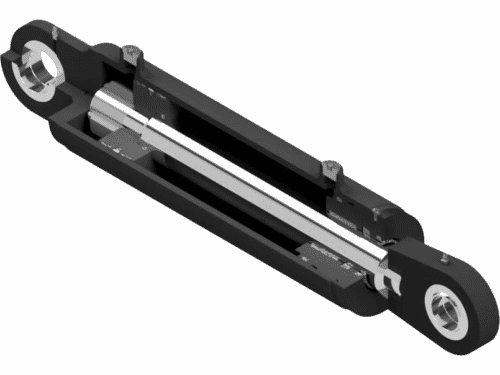

Tie Rod Hydraulic Cylinders

Manufacturers hold tie-rod cylinders together with tie rods that run the full length of the barrel. These cylinders usually feature square or rectangular end caps. High-strength steel forms the cylinder body. They normally operate below 3,000 PSI. Most tie-rod designs follow National Fluid Power Association (NFPA) standards. Those standards ensure full part interchangeability. Key standards cover bore size, rod diameter, port locations, mounting dimensions, and stroke length.

Tie rod cylinders feature simple constructions that are easy to repair in the field with common wrenches and tools. They offer design flexibility and easily accessible component part replacements, making them one of the most widely used cylinders in industrial and mobile machinery.

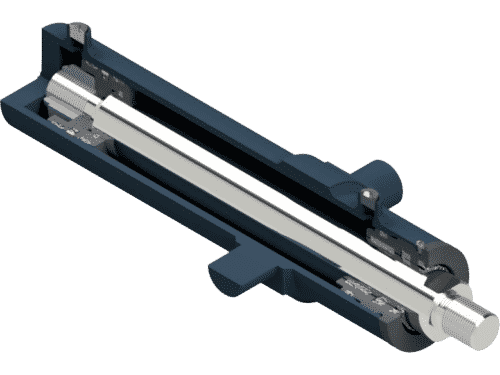

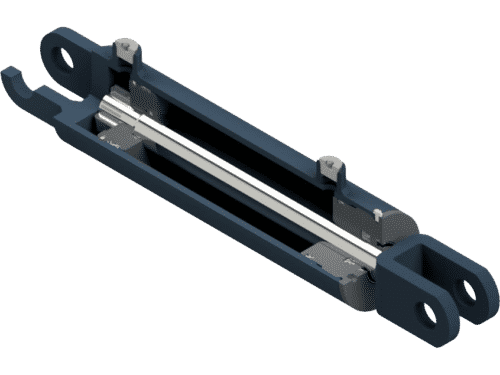

Welded Rod Hydraulic Cylinders

Welded rod hydraulic cylinders deliver more complex designs than tie-rod models. They provide compact construction. These cylinders easily withstand pressures of 5,000 PSI or higher. Manufacturers build welded rod hydraulic cylinders by welding the barrel directly to the end caps. They weld ports straight onto the barrel as well. This design lets engineers place ports freely around the cylinder’s circumference. Most designers position ports near the end or head caps. Technicians secure the front gland with bolts or threads. This setup makes servicing and maintenance straightforward.

Due to the lack of tie rods, welded rod hydraulic cylinders are much easier to keep clean as their exterior does not capture debris. They are available in single-acting or double-acting types to meet your needs and are well-suited to heavy-duty hydraulic cylinder applications.

Deciding Between a Welded Rod or Tie Rod Cylinder

The best way to decide between choosing a welded cylinder or a tie rod hydraulic cylinder is through considering the needs of your application, such as anticipated loads, operation duration, and budget requirements.

Choose a tie rod hydraulic cylinder when:

- You are conducting a low-pressure application.

- You require a cost-effective hydraulic cylinder to satisfy budget restrictions.

- Your application requires a cylinder type with uncomplicated repair, maintenance, and installation capacities.

Choose a welded rod cylinder when:

- Your application requires cylinders that can withstand high-pressure or heavy-duty uses without leakage.

- Your application demands highly durable equipment.

- Installation space is limited, or mobility is critical.

In many applications, a welded rod hydraulic cylinder can be used in place of a tie rod cylinder to lower the likelihood of leaks, provide a smooth and cleanable exterior, or increase your system’s durability.

Purpose-Built™ Hydraulic Cylinders to Meet Your Specifications

From manufacturing custom hydraulic cylinders to providing industry-leading cylinder knowledge, Aggressive Hydraulics keeps quality at the center of everything we do. If you have questions about the difference between tie rod cylinders and welded cylinders or want to learn more about your options, contact us today. For specific pricing information and to receive a quote, fill out our custom rod cylinder application. Our USA-based customer service team will be in touch to create a Purpose-Built™ cylinder that meets each of your specifications.