Hydraulic cylinders handle heavy loads and last for years, yet problems still happen. One issue can shut an entire job site down: a bent rod. Side-loading, operator error, or installing an undersized or oversized cylinder usually causes it. A bent hydraulic cylinder rod triggers leaks, cylinder damage, and sometimes complete cylinder failure — all of which cost downtime and money.

Replacing vs. Fixing Bent Hydraulic Cylinder Rods

You must act immediately after identifying a bent hydraulic cylinder rod by replacing or fixing the component.

While repair may seem more cost-effective than purchasing a replacement, this isn’t always the case. To straighten bent hydraulic rods is to postpone the purchase to a later date, as fixing hydraulic cylinder rods compromises the integrity of your cylinder. Straightened rods are weakened and make it unsafe to use your equipment for heavy loads, normal operations, or harsh environments. Incorrect installations can also damage your cylinder, making replacement costs skyrocket compared to if you had initially replaced the rod.

Before you try to straighten a damaged rod, contact your cylinder supplier or manufacturer for expert advice. For example, if only the rod took the hit, Aggressive Hydraulics can supply a direct replacement rod for all our Purpose-Built™ cylinders. We use FEA analysis, to determine whether full replacement or repair makes more sense. We also help you perform proper cylinder maintenance, so the problem never repeats.

Design Considerations to Prevent Bent Hydraulic Cylinder Rods

Bent hydraulic cylinder rods can be prevented during the design and engineering phase. By integrating these elements into your hydraulic cylinder, you can minimize shutdowns and repair costs caused by bent hydraulic cylinder rods.

Stop Tubes

Stop tubes add bearing support and minimize the deflection of the hydraulic cylinder rod. They are usually included in hydraulic cylinders with longer strokes to reduce misalignment by increasing the space between the piston and rod cartridge. In addition to preventing sideloading and bent rods, stop tubes enhance horizontal applications while avoiding jackknifing or buckling.

Mounting Options

Proper hydraulic cylinder mounts play a critical role in preventing bent rods. Spherical mounts, spherical bearing rod eyes, and trunnion mounts all help. These mounts easily absorb minor sideload and misalignment. Flexible options like spherical bearings and trunnions stop side forces before they ever hit the rod. In the field, that means dramatically fewer bent hydraulic cylinder rods end up bent.

Rod Material Choices

Many rod material options exist today. To stop bending and damage, team up with your cylinder engineer early. Choose a material with high yield strength and high tensile strength. This delivers a rod that shrugs off sideload and resists bending. The right material dramatically extends your equipment’s service life.

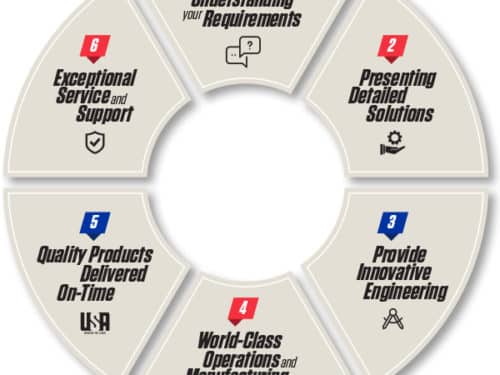

Purpose-Built™ Hydraulic Cylinders Engineered to Move Your Business

Aggressive Hydraulics is your top source for expert resources, trusted advice, and Purpose-Built™ hydraulic cylinders designed and manufactured to your specifications. We are dedicated to being your full-service problem solver, incorporating quality assurance and USA-made excellence into every order as we work as an extension of your business.

Contact us today to learn more about how we can help prevent bent hydraulic cylinder rods through reliable designs and high-performance cylinders. Request a quote to get started.