Hydraulic cylinders are built to withstand heavy loads and provide long operational lifespans, but problems can still occur. One issue that can bring a job site to a standstill is bent hydraulic cylinder rods. Generally begun by sideloading, operational error, or installing improperly sized cylinders into machinery, bent hydraulic cylinder rods cause costly downtime, cylinder damage, and even complete cylinder failure.

Replacing vs. Fixing Bent Hydraulic Cylinder Rods

You must act immediately after identifying a bent hydraulic cylinder rod by replacing or fixing the component.

While repair may seem more cost-effective than purchasing a replacement, this isn’t always the case. To straighten bent hydraulic rods is to postpone the purchase to a later date, as fixing hydraulic cylinder rods compromises the integrity of your cylinder. Straightened rods are weakened and make it unsafe to use your equipment for heavy loads, normal operations, or harsh environments. Incorrect installations can also damage your cylinder, making replacement costs skyrocket compared to if you had initially replaced the rod.

Before attempting to straighten bent hydraulic cylinder rods, contact your hydraulic cylinder supplier or manufacturer for advice on how to proceed. For instance, if only the rod has been impacted, Aggressive Hydraulics can provide a replacement rod for all our Purpose-Built™ hydraulic cylinders, evaluate if it’s better to replace or repair your cylinder using FEA analysis, and assist you as you conduct cylinder maintenance.

Design Considerations to Prevent Bent Hydraulic Cylinder Rods

Bent hydraulic cylinder rods can be prevented during the design and engineering phase. By integrating these elements into your hydraulic cylinder, you can minimize shutdowns and repair costs caused by bent hydraulic cylinder rods.

Stop Tubes

Stop tubes add bearing support and minimize the deflection of the hydraulic cylinder rod. They are usually included in hydraulic cylinders with longer strokes to reduce misalignment by increasing the space between the piston and rod cartridge. In addition to preventing sideloading and bent rods, stop tubes enhance horizontal applications while avoiding jackknifing or buckling.

Mounting Options

Proper hydraulic cylinder mounts are critical in preventing bent hydraulic cylinder rods. Spherical mounts, spherical bearing rod eyes, and trunnion mounts can compensate for certain amounts of sideloading, preventing bent hydraulic cylinder rods.

Rod Material Choices

Several material choices for hydraulic cylinder rods are available. To prevent bending and damage, work with your hydraulic cylinder engineering partner to select a material with high yield and high tensile strength. This will create a rod that resists damage from sideloading and bending to prolong the lifespan of your equipment.

Purpose-Built™ Hydraulic Cylinders Engineered to Move Your Business

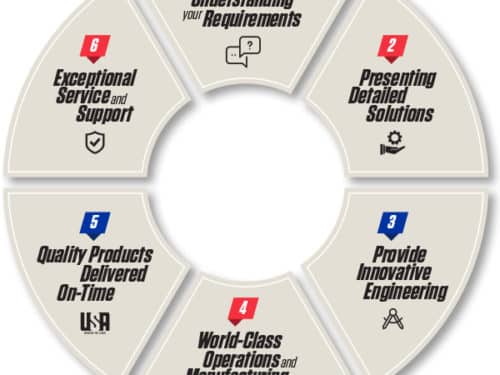

Aggressive Hydraulics is your top source for expert resources, trusted advice, and Purpose-Built™ hydraulic cylinders designed and manufactured to your specifications. We are dedicated to being your full-service problem solver, incorporating quality assurance and USA-made excellence into every order as we work as an extension of your business.

Contact us today to learn more about how we can help prevent bent hydraulic cylinder rods through reliable designs and high-performance cylinders. Request a quote to get started.