Custom hydraulic cylinders can help improve performance and extend the service life of your equipment. Just because a cylinder manufacturer offers customization doesn’t mean their product is right for you. Lower quality cylinders can cause mechanical issues over time or accelerate equipment wear. These same issues can occur when a cylinder isn’t designed to match your operational and environmental requirements.

Going the custom route is a worthwhile investment, but you also want to make sure that you get the best results for your money. Here’s what to look for when choosing a custom hydraulic cylinder manufacturer:

Choosing a cylinder manufacturer with design expertise is critical in preventing hydraulic failure and other issues caused by using a cylinder that can’t handle the demands of your equipment or application.

An experienced cylinder manufacturer should also have engineers available to answer your questions and provide guidance on what type of cylinder you need to achieve the best performance. They will ask about your application, operating environment, and discuss cylinder challenges you’ve had in the past.

This information is useful because it helps them determine everything from the materials required, load requirements, what type of fluid the cylinder is rated for, etc.

Certified Quality Standards

Quality is everything. The best custom hydraulic cylinder manufacturers have structured processes and are ISO 9001 certified for quality control. Facilities with this internationally recognized Quality Management System Standard are focused on continuously improving processes to ensure their customers’ quality expectations are met.

If you don’t see a custom cylinder manufacturer’s quality statement or certifications listed on their website, make sure you ask about them.

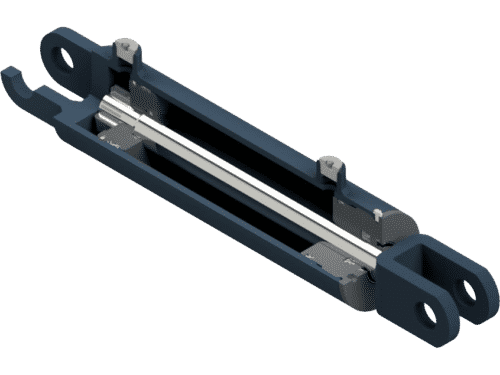

Flexible Hydraulic Cylinder Designs

What do you need the hydraulic cylinder to do? Some manufacturers consider slight design modifications or different material variations of the same design “custom.” And for some users and applications, that is just fine. Maybe all you need is a different material or a bore size to be slightly modified to fit your equipment. But a genuinely custom hydraulic cylinder design goes beyond that.

Here are customization offerings to look for when choosing a cylinder manufacturer:

- Body Material: Do they offer different material and plating options? What works for a construction environment isn’t the same as what you need for offshore drilling and oil. Operating temperature is also a critical factor in the selection of the seal package.

- Configuration: Do you need a welded rod cylinder, telescopic cylinder, smart sensing cylinder, mill duty cylinder, or something else? Make sure the manufacturer you choose offers the right option for your application.

- Mounting: Hydraulic cylinders typically come with fixed, pivot, or offset mounts, though some designs require something different.

- Rod and Bore Sizing: Top hydraulic cylinder manufacturers know how to size bores and rods to meet your force requirements.

- Stroking Distance: This measurement determines the cylinder configurations needed and ties into your pressure rating requirements.

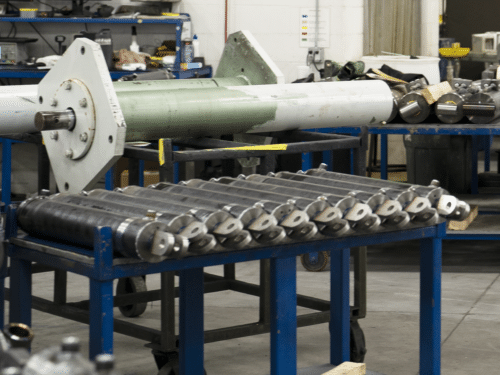

There are custom hydraulic cylinders, and then there are application-specific hydraulic cylinders. Aggressive Hydraulics designs cylinders to meet your specific requirements. Our Purpose-Built™ cylinders are made in America and are designed to expand the lifespan and efficiency of your equipment. A reputation built on quality and performance has made us a top custom cylinder manufacturer.

Let our engineers design a custom hydraulic cylinder for you that gets the job done right. Give us a call at 866-406-4100 to speak with a cylinder expert.