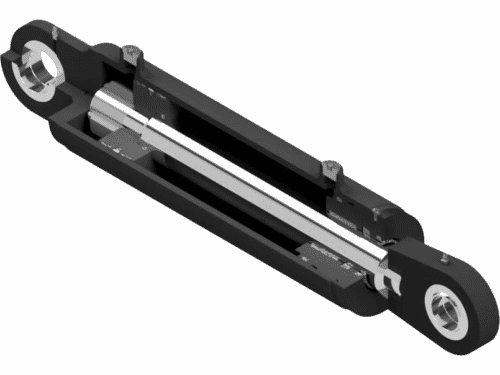

Hydraulic cylinders are a workhorse of fluid power system in industrial and mobile machinery. However, one drawback to hydraulic cylinders is that the retracted length is always greater than the stroke, presenting a problem in applications requiring a shorter retracted length. For these applications, multistage hydraulic cylinders are an ideal solution as they feature two or more moving stages to provide longer strokes relative to the retracted length.

Potential Issues with Conventional Multistage Hydraulic Cylinders

Most double-acting multistage hydraulic cylinders use split cast iron rings in place of typical elastomeric piston seals. Although these cast iron rings are robust and durable, they allow some bypass leakage and cause the cylinder to drift under load. This can create unwanted outcomes such as a boom left up in the air lowering to rest on the ground or an induced tensile load allowing the cylinder to drift out.

Cylinder Drift

One of the main causes of decreased multistage hydraulic cylinder performance is hydraulic cylinder drift. Drift occurs when internal leaks across the piston cause unequal pressure within the cylinder, creating an imbalance. Your equipment’s movements will become rough and uneven, resulting in full system failure if not promptly addressed.

Pressure Intensification

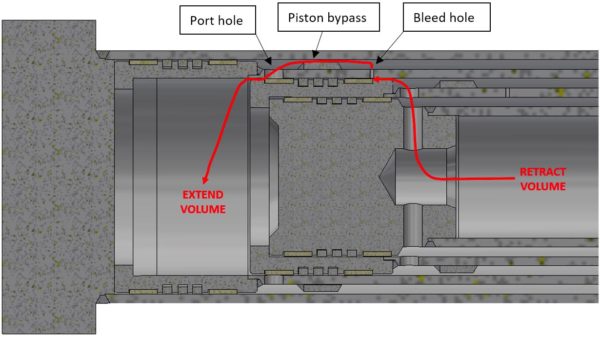

Pressure forces within a hydraulic cylinder should remain balanced. However, when the bore end is supplied pressure and the port end is blocked, pressure intensification can occur, triggering critical consequences for your equipment. Conventional telescopic cylinders often include a smaller port hole through each stage, allowing trapped fluid to escape and prevent catastrophic failure.

If the piston stops between the two ports and low flow is sent to retract the cylinder, the flow may bypass the piston by entering the smaller port and exiting the larger port to the extend side. The cylinder will stall until the flow increases and the pressure drop across the port holes exceeds the pressure required to retract the load.

Illustration provided by Aggressive Hydraulics Engineering Department.

Location of Working Ports

With the conventional double-acting telescopic cylinder, the retract port must always be in the end of the smallest moving stage, also known as the plunger. The extend port may be in the main barrel or the plunger end. In many applications, it is preferred for the larger, heavier main barrel to be fixed to the machine and the smaller, lighter plunger to be attached to the moving machine member. Therefore, to use a conventional design, a decision must be made between managing moving hoses or connecting the heavier main barrel to the moving member while consolidating hose connections on the plunger.

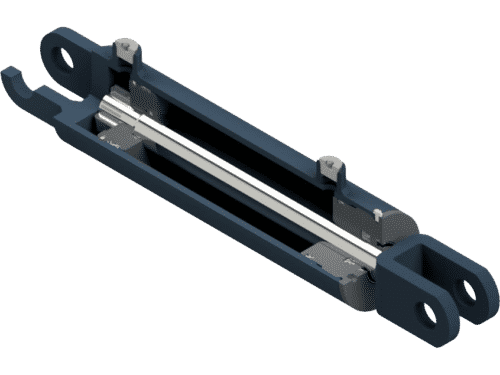

Enhance Multistage Hydraulic Cylinder Performance with Double Wall Designs

One way to minimize these potential issues with multistage cylinders is to utilize a custom-built double wall cylinder. Double wall hydraulic cylinders are an enhanced double-acting telescopic design. The intermediary stage or stages are comprised of two concentric tubes with a flow path between them. The pistons do not cross port holes, allowing low-leakage elastomeric seals to be used. Other advantages include the ability to:

- Hold a position against an induced load without drift when paired with a load-holding valve.

- Move smoothly across a wide flow range, including very low flows.

- Eliminate the potential for pressure intensification on the annular volume

- Eliminate the potential for stalling due to bypass around the piston

- Locate both ports on the barrel to simplify hose connections.

The Benefits of Double Wall Multistage Hydraulic Cylinders vs. Conventional Equipment

There are many markets and applications in which the benefits of the double wall telescopic hydraulic cylinder provide tangible value to OEMs and end users. They significantly reduce the risk of unintended motion due to failure of a hose or threaded fluid connector, providing an increased level of machine safety. Additionally, the double wall telescopic cylinder outperforms conventional cylinders to meet the rigorous requirements of industrial operations:

| Application Requirement | Conventional Telescopic | Double Wall Telescopic |

|---|---|---|

| Resist upward digging forces | Allows movement due to piston leakage | Holds position with positive piston seal |

| Hold digging wheel in raised position | Drifts down due to piston leakage | Holds position with positive piston seal |

| Precise positioning at low speed | Erratic & jumpy at low flow | Smooth operation at low flow |

| Reliable operation | Retract stalling at low flow and pressure intensification during mis-staging are potential failure modes | Operates without stalling and without potential of pressure intensification |

| Port location | Retract port must be located on the moving plunger | Simplified plumbing with both ports on the barrel. |

Purpose-Built™ Multistage Hydraulic Cylinders with Double Wall Constructions

Contact Aggressive Hydraulics today to learn more about how double wall multistage hydraulic cylinders can increase the efficiency of your industrial or mobile equipment.