Hydraulic Cylinder Drift Causes and Prevention

Have you experienced slow, sluggish, or unusual movements and changes in the position of your cylinders when you operate your machinery? Or maybe you notice that the cylinder slowly sinks while holding heavy loads. What’s happening in these cases is hydraulic cylinder drift—it’s one way a hydraulic cylinder can malfunction. Although the issue could be a system issue, let’s focus on cylinders.

What Causes Hydraulic Cylinder Drift?

Hydraulic cylinder drift can be caused by an internal leak in the cylinder across the piston or an external leak. When internal leaks occur, the hydraulic fluid physically moves from one side of the piston to the other, creating an uneven distribution that causes the cylinder to move or “drift.”

Leaks generally occur when the piston seals, holding valve, or rod seals wear out or are compromised due to various reasons. One cause of hydraulic cylinder drift is contaminated hydraulic fluid, which can damage seals and/or sealing surfaces.

Why You Should Never Ignore the Signs of Hydraulic Cylinder Drift

Hydraulic cylinder drift is problematic for a few reasons. First, drift can cause jerky hydraulic movement in equipment that once operated smoothly. When we’re talking about equipment that lifts several tons, this can be a serious safety hazard.

In addition, uneven distribution of hydraulic fluid can increase the distribution of forces and respective pressure put on one area of the equipment, leading to failure. Again, this creates a hazardous situation when you’re lifting, holding, and moving heavy loads.

Diagnosing hydraulic cylinder drift the moment you start seeing issues will help you prevent costly equipment downtime and potential collateral damage to the hydraulic system or equipment. Always inspect your hydraulics regularly and only operate equipment within the manufacturer’s recommended speed and load capacities.

Tips for Hydraulic Cylinder Drift Prevention

Hydraulic cylinder drift is a sign that the cylinders are not performing efficiently and as originally designed. Ignoring the issue will only make things worse by creating an unsafe work environment and further damaging your cylinder components and equipment. Both the risks and the financial ramifications of equipment failure are significant. However, there are steps you can take to protect yourself and your machinery.

It All Comes Down to Choosing the Right Product

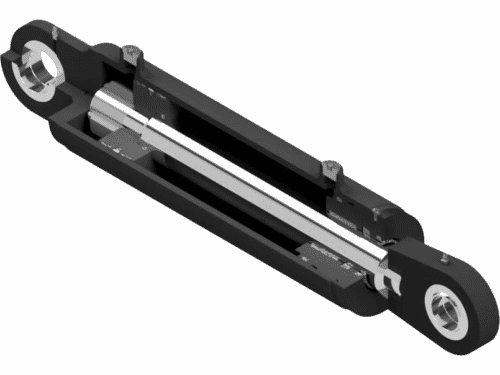

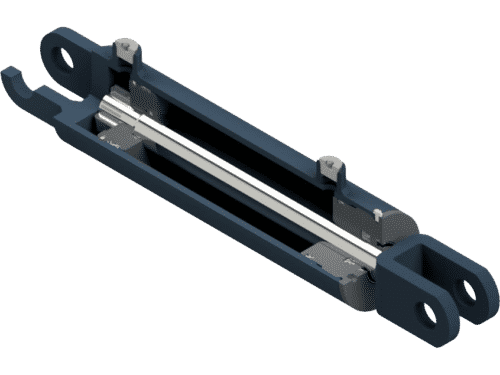

The number one thing you can do to prevent hydraulic cylinder drift and failure is using high-quality, Purpose-Built™ cylinders. Rather than choosing a generic, all-purpose cylinder, we recommend selecting Purpose-Built™ cylinders for your business. These cylinders are built specifically for your industry and equipment, so they are guaranteed to perform at a high level.

Stay on Top of Maintenance

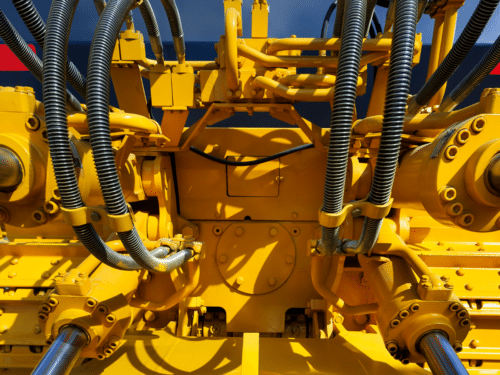

Performing regular maintenance is also extremely important. Take good care of your machinery, and your machinery will take good care of you! Routine maintenance for your hydraulic cylinders should include fluid conditioning, always using high-quality filtration and monitoring capacity levels, and inspecting the rods for straightness, damage, and mount and pin condition. If any parts look even slightly worn or damaged, don’t delay in getting them replaced.

Do you want to take the first step to prevent cylinder performance issues? Contact us today to find out more about our Purpose-Built™ hydraulic cylinders. We’ll work with you to design the right cylinder for the job, and we’ll help you maintain it so it will work hard for years to come. Questions? Give us a call at 866.406.4100.